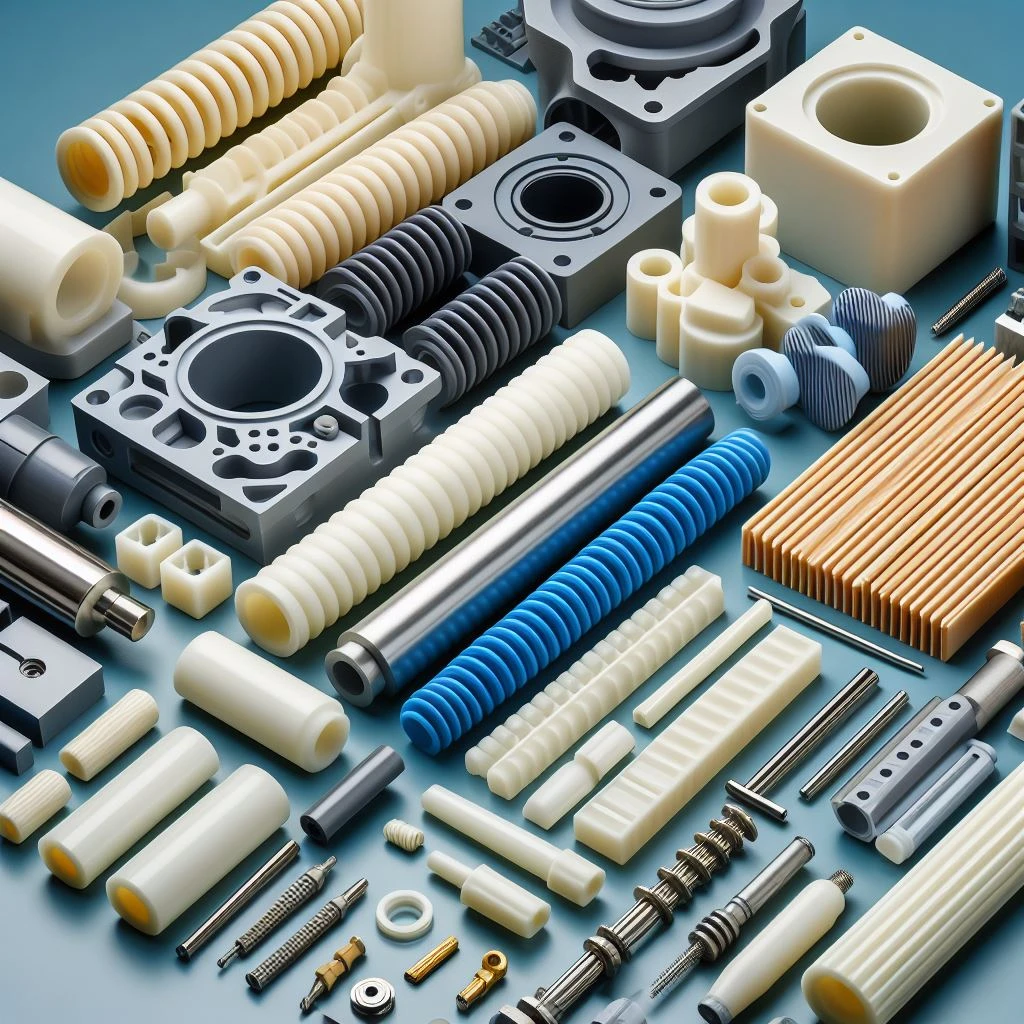

At DIPMA, we offer a wide range of high-quality engineering plastics, such as Nylon, UHMW, Acetal and PTFE, each with unique characteristics that make them ideal for different industrial applications. While they are all plastic materials, there are important differences among them in terms of strength, hardness, working temperature, and other factors.

One example of these differences can be seen in the use of bushings for the food industry. In this application, the Nylon and Acetal are two commonly used engineering plastics. Nylon is resistant to abrasion and deformation, with high load-bearing capacity and good chemical resistance. Acetal, on the other hand, offers excellent wear and impact resistance, making it ideal for applications that demand high mechanical strength and dimensional stability.

In comparison, the UHMW is an engineering plastic used in applications that require excellent wear resistance, low friction, and high impact strength. On the other hand, the PTFE is used in high-temperature applications and in contact with aggressive chemicals, thanks to its excellent chemical and thermal resistance.

Each engineering plastic has unique characteristics that make it suitable for different needs and applications in the industry. Our sales team is always available to advise and guide our customers in selecting the right engineering plastic for their specific application.

If you’re looking for innovative engineering plastic solutions, don’t hesitate to contact us and discover how we can help you improve your processes and boost efficiency in your business.